|

Harvesting

- Harvesting is a labour consuming, expensive and tedious operation. The moisture content of the soil at the time of harvesting indicates the ease or difficulty with which harvesting can be done.

- Groundnut plant has an indeterminate growth habit. Flowering extends over 2 months in Spanish-bunch types and over 3 months in Virginia-runner types. It takes about 60 days for the pod to develop fully after the flower appears. It is therefore, usual to find pods in different stages of maturity at harvest.

- It is difficult to fix optimum time for harvesting when the greatest proportion of high quality sound matured pods is obtained.

- If harvesting is done early, large number of late formed pods will be immature. If harvesting is done late, either the early formed pods would get separated from the plant and remain in the soil or large number of fully developed pods of bunch varieties would germinate on the plant itself if there is a rain.

- The quality of the foliage which are used as cattle feed will also deteriorate if they are soaked in rain at the time of harvesting and drying.

- Therefore, it is essential to fix the proper time for harvesting when maximum yield of best quality pods and haulms with high shelling out-turn, test weight of kernels and oil content can be obtained.

- When good percentage of pods is well developed and fairly intact on the plant, the plant turns yellow and leaf shedding starts.

- The maturity of pods is determined by their attaining normal size of the genotypes, veins becoming conspicuous, the inside of the shell turning dark, the kernel reaching maximum development and testa having normal colour of the genotype.

- The duration of the crop is influenced by the soil type, weather condition, cultural practices followed and the genotypes.

- The proper stage for harvesting is determined by pulling out a few plants at random and examining for the maturity of pods. This should be done at intervals of a few days when maturity period specified for the genotype is approaching. When high percentage of pods (about 75%) matures, harvesting has to be commenced.

Pulling and Stripping

- Harvesting should be done in bright sunny days so that the pods and vines can be dried properly. Humidity should not be high at the time of harvesting as molds develop on the pods and affect quality.

- Harvesting consists of 2 stages. The plants have to be lifted from the soil with pods intact and then the pods have to be separated from them.

- Lifting of plants with pods intact from the soil is done by manual labour or bullock-drawn blade harrows or tractor-drawn diggers. In certain areas, the plants are uprooted with country plough and the plants and pods are picked by manual labour. The pods leftover in the soil are picked by hand.

Groundnut harvester

- For harvesting and winnowing groundnut crop at soil moisture levels of 8-15%, this harvester is used. This tractor-mounted implement covers an area of 2 hectares per day and the cost of operating the implement is Rs.660/ha. The cost of the unit is Rs.20,000/-

- Stripping of pods from the plants is done by several methods.

- In bunch types, the plants are stacked in heaps with pod ends exposed. The pegs become brittle within a week and the pods are stripped with hand.

- In some areas, the pods are stripped by hand immediately after pulling out from the soil on the same day. For this purpose a simple comb-type stripper and groundnut thresher are available and these are useful for bunch types.

- One more powertiller operator groundnut harvestor is developed by TNAU which is suitable for harvesting all varieties of groundnut.

- It is suitable for all makes of 10-12 hp powertillers.

- It saves time and labour.

- The cost of the unit is Rs.7000/-

Groundnut thresher

- Manual method of removing groundnut pods from groundnut plants takes 175-200 women hours per hectare. Since it is a labour intensive operation, scarcity of labour is often experienced during peak harvesting seasons.

- The power operated throw-in type groundnut thresher suitable for freshly harvested groundnut crop will be of immense use to the groundnut growers.

Salient features

Capacity - 150 kg pods per hour

Labour requirement - 2 men and 2 women

Saving in cost - 32%

Saving in time - 70%

Cost of equipment - Rs.30,000/-.

Impact type groundut stripper

Special features

- To remove groundnut pods from vines

- Operated by 2.5 HP kerosene engine

- Operator assisted by two helpers

- Suit to the requirements of m

- edium and small farmers

- The vines are not fed into the stripper hence the fodder value of the vines is maintained

- Cost of the machine is Rs. 19,000/-

- Saves labour cost.

Top Top

Drying and Cleaning

- At the time of harvesting groundnut, pods usually have a moisture content in excess of 40% (wet basis) and vary widely in physiological maturity. The pods have to be cleaned and dried to bring down the moisture to 10% or less for safe storage or marketing.

- Fungi attack groundnut pods after lifting during drying and storage whenever environmental conditions are favourable for their growth and development.

- Drying has to be done rapidly to prevent molding or other forms of deterioration but not very rapidly as to lower the quality. This will help in maintaining the desirable flavour, texture, germination and overall quality.

Top Top

Storage

- After cleaning and drying of groundnut pods to a safe moisture level, they have to be stored to keep them dry and protected against insects and rodents to

prevent loss of natural colour and flavour and absorption of off flavours and development of rancidity. * Hence proper storage of groundnut pods is an important step whether the pods are used for oil extraction or seed or for edible purpose.

Storage Structures

- Farmers usually dispose off their groundnut pods (apart from the quantities retained by them for seed and edible use) within 3-4 weeks or sometimes 3-4 months depending on their economic conditions.

- Pods used for seed purpose are stored for 7-8 months and those intended for edible purposes are stored till the commencement of next harvesting season.

- Storage is invariably in the form of unshelled pods. Pods for seed purposes are generally stored in earthen pods, mud bins, bamboo baskets or wicker baskets which are often plastered with mud or cowdung.

- Gunny bags are also sometimes used for storage. Pods kept in gunny bags are more liable to be damaged by dampness, rodents and other storage pests.

- In the regulated markets, decorticating factories and oil mills, the pods are generally stored loose in godowns or in gunny bags. Pods are also heaped loose or stacked in gunny bags in the open if rains are not expected. The stacks are covered with tarpaulin or gunny cloth.

- As the kernels are more liable to damage faster than pods, they are shelled only a week or two before they are required.

- At the terminal markets and ports storage is in the form of kernels which are most often packed in gunny bags. The pile of bags in godowns is kept 4-5 feet below the roof to allow free circulation of air. The floor is sometimes covered with matting to prevent dampness.

- The problems of storage in groundnut are of greatest significance in our country on the account of the high temperature in summer when bulk storage is required.

- Kernels deteriorate faster than pods as the shells afford protection for the kernels against pests and protect the desirable qualities in them. However, the extra space required for unshelled pods makes it impractical to store large quantities. Huge losses are sustained to store annually by the growers, traders, millers and processors.

The following aspects are to be considered for better storage of groundnut

- All produce intended for storage should be well dried to have not more than 5% moisture.

- As far as possible groundnut should be stored as pods rather than as kernels.

- If storage is to be done as kernels, pods should be decorticated carefully to avoid splits and broken in kernels. The period of storage as kernels should be reduced to the minimum possible.

- Storing of kernels on hard floor or hard bedding material and piling of bags to great height should be avoided to minimize caking up of kernels and damage to gunnies.

- Produce from the summer crop should not be stored for a long period as it deteriorates more rapidly than that from the winter crop. The summer produce is best utilized for local crushing.

- For storing small quantities of kernels, bins appear to be most suitable.

- Deterioration of groundnut can be considerably reduced by storing them in properly built stores.

- The most satisfactory stores are those which have good cement floors, well-plastered walls, proper and adequate windows and ventilators and tight fitting doors. A tin strip fixed along the bottom 10 to15 cm of the doors passing its lower end below the door to the other side will make the doors rat proof.

- Windows should be at last 3 feet above ground level and half-an-inch wire mesh should be fixed on them to prevent damage by rodents.

- The stack base should be on raised stands not touching the hard flooring. Sand should be spread on the floor to about a foot high and covered with a gunny cloth. Stacks should be in not more than 10 bags piled one over the other depending upon the height of the godown and the space available. The pile of bags has to be kept 4-5 feet below the roof to allow free circulation of oil.

- About 20% of the total space should be allowed between the top layer of the stack and ceiling. Each stack has to be separated from the wall and its neighbour by about 2 feet for ventilation and proper inspection. Ventilators should be kept open only on dry days.

- Gunny bags should be cleaned before use to get rid of dirt and insect pests. Spoiled seeds should be removed daily and the torn bags containing pods should be replaced immediately.

- The store should be cleaned thoroughly each season. Split kernels, groundnut shells, cobwebs and other debris should be completely removed.

Top Top

Storage insect pests

- Several insects attack groundnut and its products in storage. Approximately 6-10% of the groundnut kernels stored in bags are damaged by insects.

- Insect infestation causes loss in dry mass of the kernels, increased levels of free fatty acids in the oil (thereby lowering the quality) and if the seeds are heavily damaged, reduction in germination potential. The heat and moisture generated by large insect population within heaps or stacks of groundnuts may also increase the risk of mold growth.

- The major pests of stored groundnuts in India are groundnut bruchids, red-flour beetles, rice moth, saw-toothed beetle and almond moth.

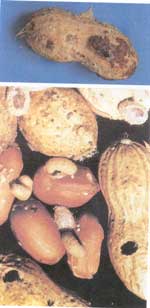

Groundnut bruchid

|

|

- It is generally regarded as the only species

that can penetrate intact pods to infest the kernels.

- The adult [Caryedon serratus (Olivier)] is a

reddish-brown beetle about 4-7 mm long and 5 mm

wide, with large hind legs. The translucent milky

white eggs (1 mm long) are attached to the pod

wall. After hatching, the larva burrows straight

through the egg shell and the pod wall, and starts

eating the seed.

- ;The first sign of attack is the appearance

of window's cut into the pod after emerging from

the pupal cocoon. Fully-grown larvae sometimes

come out through the exit holes made by previous

generation.

- Severely infected seeds are too badly damaged

for human consumption or oil expulsion.

|

Red-flour beetle [Tribolium castaneum (Herbst)]

|

|

- These are elongate, reddish-brown insects approximately

3- 4 mm long. The larvae are brownish-white and

somewhat flattened in appearance. Adult flour

beetles may live up to 2 years but the average

life is one year.

- The development period from egg to adult is

about 20 days under optimum conditions.

|

Rice moth [Corcyra cephalonica (Stainton)]

- The adult moth is brown and 12-15 mm long with a wing expanse of 20 mm. The fore-wings are uniformly coloured, greyish-brown without spots but with slightly darkened veins. The head bears a projecting tuft of scales.

- The adults do not feed but the female lays up to 150 eggs within few days of emergence from the cocoon.

- The larvae are mobile and feed upon and within the kernels. Infestation causes aggregation of kernels by presence of webbing. When mature, the larva constructs a cocoon, which may be distinguished from those of other moth species by its opaque white appearance and extreme toughness.

- The development from egg to adult is completed in 4-5 weeks.

- It prefers sorghum followed by maize, groundnut, wheat and rice.

Saw-toothed beetle (Oryzaephilus surinamensis Linn.)

- The adults are about 2.5 mm long and brownish; the thorax bears 6 saw-tooth-like projections on each side. The whitish larva has a brown head, which is small, slender and slightly longer than the adult. Each female is capable of laying 300 eggs loosely on groundnuts. Both adults and larvae feed on the produce and the adults may live for up to 3 years.

Almond moth[Ephestia cautella(Walker)]

- This is a pest of groundnut and groundnut products.

- The adults are greyish-brown with an indistinct pattern on the fore-wings. This moth is smaller than rice moth, being 6-9 mm long at rest.

- The female lays about 300 eggs often by simply drooping the eggs through holes between the fibres in jute bags or they are laid freely on the surface of the kernels. The adult moths do not feed, live for less than 14 days and the eggs are laid within 3 or 4 days of emergence.

- The larva is whitish which may be tinged with pink and green. The larvae move freely through the produce, contaminating it with webbing and frass. They feed on the kernels until they are full-grown.

- The egg to adult period is completed in about 25 days under normal conditions.

Pod sucking bug[Elasmolemus sordidus(Fab.)]

- The injury to groundnut is not easily visible. Both nymphs and adults suck the oil from kernels by feeding on freshly harvested pods in field or in storage. Such pods have shells spotted with excreta and kernels lose viability.

- The females lay eggs on soil. Freshly laid eggs are dull-white but turn pink before hatching. They hatch in 9 days. The nymphs turn into adults in about 4 weeks. The insects assemble in large numbers under groundnut haulms.

- Soil application of malathion 5 % D @ 25 kg/ha at the time of last plough minimizes the damage by the insect.

Management of storage insect pests

- Groundnuts must be dried properly after harvest to reduce the moisture content of the kernels to below 7%, the upper limit for safe storage. At high moisture levels, insect populations develop more rapidly and there is an increased risk of invasion by toxigenic fungi, with a consequent danger of aflatoxin contamination.

- The empty stores may be disinfected with dichlorvos as a space treatment before storing the produce.

- The stacks should be constructed on wooden pallets to reduce the possibility of ground water seeping into the bottom sacks.

- For large scale storage, the most suitable fumigants are methyl bromide and phosphine.

- The recommended dosage of methyl bromide is 10-15 g/m3. There are drawbacks in using this fumigant. Inorganic bromide is retained in the oil of groundnut kernels, so treated stocks must be promptly ventilated on completion of the operation, in order to minimize residues. Repeated application of methyl bromide can reduce the germination potential of groundnuts kept for seed, particularly if their moisture content is high.

- Phosphine is usually formulated as tablets or pellets of aluminium phosphide that release phosphine gas when in contact with moisture in the air. This is applied @ 3-5 tablets or 25 pellets /t. After a fumigation period of 5-10 days, the produce should be aired thoroughly and if possible the spent fumigant should be removed.

- For small scale storage, one pellet (0.6 g) of aluminium phosphide placed on the top of groundnuts in polyethylene-lined sacks gives satisfactory control.

- Liquid fumigants such as ethylene di-bromide (EDB) and carbon tetra-chloride (CTC) at 1:8 ratio @ 12 ml/100 kg of produce are recommended.

- Admixture of abrasive materials such as fine sand, kaolin or wood ash to protect grain in farmer-level storage.

- Use of certain plant materials such as crushed neem seed, neem leaves or neem oil, which have an antifeedant or repellant effect on storage pests.

Top Top

|