|

Curing of Tobacco Leaves

Curing in China

|

- Curing is probably the most important operation in the

production of tobacco and the method and efficiency of curing

determines, to a large extent, the quality of the product.

- Curing of tobacco is a process by which the harvested leaves

are made ready for marketing.

- In more technical terms it may be stated that curing is a

process of drying decomposition of chlorophyll until the green

colour disappears from the harvested leaves, hydrolysis of

starch into sugars and respiration or fermentation of sugars

there after.

- In curing, the mineral salts also crystallize out producing

the grain of the leaves.

- The sole object of curing is to dry the green leaf in such

a way that the final product has required colour, texture

and aroma.

Methods of Curing

- The methods of curing adopted in India are governed with

several factors

- Tradition

- Convenience

- Market value of finished product

- Economic considerations.

- Depending on the type of tobacco, the method of harvest and

maturity of leaves at harvesting, there are four distinguished

methods of curing in India.

- Air-curing

- Fire curing

- Sun curing

- Flue curing.

Top

Top

Stages of Curing

The stages of curing are

- Yellowing of leaf,

- Fixing of colour,

- Drying of leaf

Yellowing of leaves

- In the yellowing process of leaves, which usually requires

24-36 hours or slightly longer, only gentle heating is done

with a temperature ranging between 90 to 100° F and relative

humidity between 85 to 90 per cent.

- It is a slow starvation process and the objective of slow

heating is to give optimum humidity and retain as much moisture

in the leaves as is possible keep them alive for 30-36 hours.

- At the end of this stage the leaves attain a bright lemon

yellow colour and the starchy matter in them gets converted

into sugars.

Fixing of colour

- The fixing of colour takes another 24 to 30 hours for

completion. The stage, being very critical, should be attended

to with utmost care because slight change in temperature deteriorates

the quality, which lowers the market price.

- The temperature of the barn should be gradually increased

when yellowing is over with a decrease in the humidity by

opening the ventilators.

- Any delay in drying of leaves, after yellowing is over, results

in the development of a brownish tinge on the yellow leaves

called "Sponging" due to oxidation of tannin like

substances.

- But, on the other hand, a sudden rise in the temperature,

when the leaves are still wet, results in a bluish balck discolouration

called "scalding".

- The fixation of colour merely involves drying of the tissues

to the point where oxidation of colour producing matter cannot

take place.

- Ample ventilation is provided so that relative humidity of

the barn is effectively reduced and the temperature is advanced

at the rate of about 4-6 degress per hour until it reaches

to 140° F which is maintained until the leaf blade becomes

practically dry.

- At this stage about 80 per cent of the leaf moisture is driven

off.

- This process consists of nothing but drying of midrib of the

leaves. During this process the ventilators are closed for

conservation of heat.

Temperature of the barn is advanced at the rate of 15°

- F per hour until it reaches to 170 to 180° F and the temperature

is maintained for 18-24 hours for completion of drying process

of midrib in all parts of the barn.

- This way the entire process of flue curing usually requires

about 84-96 hours.

- After drying, the leaves are generally left in the barn overnight

with doors and ventilators opened so that the leaves may absorb

moisture from the atmosphere and permit their handling next

morning otherwise they will remain very brittle and break

into pieces while handling.

- To achieve softness in the leaves, sometimes water is sprinkled

over the floor of the barn and doors and ventilators are closed

at night.

- The cured leaves are reduced to about 10 to 20 per cent of

their green weight which possess a moisture ranging between

8 to 18 per cent after curing.

- A nicely cured leaf should be of bright lemon yellow colour,

fine and silky texture, no blemish, mild strength, slow, regular

and continuous burning character, white ash, and pleasant

and neutral aroma etc.

Top

Top

Factors affecting the attainment of good cured quality of tobacco

- The important factors, which are resp onsible for

the quality of the finished product are mentioned below.

Temperature

- Curing is a vital process in production of quality tobacco,

and it is expected to proceed normally within the prescribed

limit of temperature.

- A temperature below or above the normal limit will inhibit

or slow down the curing process but the drying will not necessarily

be stopped and in fact it may be accelerated.

- Temperature should be within 60 to 180° F depending upon

the stage of curing.

Relative humidity

- Relative humidity is highly important in influencing the

rate of drying.

- It is observed that within normal curing temperature the actual

rate of drying in the air curing process is relatively slow,

requiring several weeks for completion whereas, in the flue

curing, the whole process is completed within 3 to 4 days.

- On an average the relative humidity should be 85 per cent

at beginning but after the leaves begin to turn yellow a lower

humidity that permits a rapid drying is advised.

Air supply

- Curing is largely a process of oxidation in which an adequate

air supply is required.

- Normally the air supply is met with when ventilators are opened

to regulate the humidity of the chamber.

- Opening of ventilators governs the exposure of leaves to the

light.

- Total darkness is not a necessary condition for successful

curing whereas bright light may be injurious in some types,

especially it affects the colour of the cured products.

Condition of the leaf

- The capacity of tobacco to be cured and the extent of

the process depend on the type of leaf involved, the condition

under which it was produced and the amount of tobacco mass,

its degree of maturity and other physical characteristics.

Top

Top

Air Curing

- In air curing the source of energy is the atmospheric

temperature carried through air.

- The leaves are spread in the shade either in a barn or in

a shed for curing.

- A proper regulation of atmospheric temperature, oxygen and

humidity results in a better quality cure. There are two stages

of air curing.

- Yellowing of leaves

- Development of brown colour.

- As such this method has very little value for curing a high

grade tobacco as the leaves give up their moisture slowly

and turn finally to a brown colour.

- The methods adopted for curing differ from place to place.

- Air-curing is commonly adopted in West Bengal, Bihar, Uttar

Pradesh, Madhya Pradesh, Punjab, Karnataka, Andhra Pradesh

and Tamil Nadu. There are three main methods for air curing

viz.

- Ground-curing

- Rack-curing

- Pit-curing

Ground-curing

- In Uttar Pradesh the popularly grown hookah tobacco is

slowly cured in heaps on the ground. At Kampil in Faraukhabad

district, which is famous for its hookah tobacco, the wilted

plants are cut and collected into heaps and are left in the

field for two days after which the leaves are separated and

tied into a bundle of two or three leaves.

- These bundles are again heaped up and stored on a farmstead

and turned occasionally till finally cured.

- The chewing tobacco of Karnataka, after whole plants are cut,

is allowed to remain on the ground for six days after which

they are turned over in the early morning to expose the other

side.

- These fully exposed plants are taken to the curing-shed where

they are bulked and rebulked for 15 to 20 days. The leaves

are then separated from the plants and tied into bundles according

to their length or size.

- In this, matured leaves are harvested by priming method and

they are tied into bundles containing 4 to 6 leaves according

to their size.

- These bundles are then strung on a jute string, which are

fixed on specially erected bamboo poles in a barn.

- A required atmospheric temperature and relative humidity of

70-80 per cent is maintained by either closing or opening

the ventilators or sprinkling water inside the barn. The curing

process takes about 5 to 6 weeks time.

- The rack-curing is usually adopted in following areas

- Tamil Nadu for country cigarette, cigar, cheroot, chewing

and snuff tobacco.

- Maharashtra for bidi and chewing tobacco.

- Andhra Pradesh for cheroot and bidi tobacco.

- Assam for hookah tobacco.

- Lanka tobacco leaves in Andhra Pradesh are strung on ropes

in shed for 30-45 days for curing and developing yellowish-brown

colour of the leaves.

Pit-curing

- The pits, prepared in the ground, are used for curing

the tobacco leaves. However, the method is not very common.

Pit curing is mainly adopted in Punjab, Tamil Nadu, Maharashtra

and Andhra Pradesh.

- The tobacco grown in Jullundhar and Firozepur districts of

Punjab are pit cured.

- In this method the pits are lined with tree leaves or dried

straw in order to prevent mixing of leaves with soil. Then

the wilted plants are arranged in layers into small heaps.

- In Ferozepur, a layer of Aak (Calotropis sp.) leaves are placed

between the layers of tobacco leaves for increasing the pungency

of cured leaves.

- The top of the heap is covered with a layer of straw and then

with soil which should be about 10 to 15 cm above the ground

level so that rain water does not percolate into the pit.

- It takes 6-8 days for curing after which they are twisted

into ropes or made into bundles.

- The pits must be opened at right time as any delay in opening

causes overheating and the leaves will be spoiled.

- Sometimes leaves are placed in the first pit for 24 hours

and then transferred to the second pit for 48 hours and then

back again to the first for another 24-48 hours. Thus a quick

fermentation takes place and the leaves attain a dark brown

colour and fruity smell.

Fire-curing

- Fire is used as the source of energy and the jaffna tobacco

(a chewing type) in Ceylon and in Tamil Nadu are cured by

this method.

- The harvested leaves are wilted for few hours in the field,

tied into bundles of 3 to 4 leaves and hung on racks in a

smoke-hut.

- They are then smoked for 12 hours by burning coconut husk,

leaf, stalks, etc. and stocked for 3 days and again smoked.

- During the smoking treatment the creosotic substances produced

from the smoke are absorbed by the tobacco that impart a particular

taste and antiseptic properties in the leaves.

- The leaves are fermented in bulks for 3 to 4 weeks after smoke

treatment and then treated with salt water from the lagoons

or with jaggery for a special or peculiar taste of this type.

Top

Top

Flue Curing

- Flue-curing is an improved method of curing. The curing

consists of drying green leaves under artificial atmospheric

conditions by adopting a process which does not allow the

green leaf to come in direct contact with smoke or flames

of the fuel and which permits the regulation of temperature

and humidity.

- The main feature of flue curing is the drying of leaf under

controlled conditions, where the starch gets converted into

sugars and the green tobacco becomes bright, aromatic and

fine textured.

|

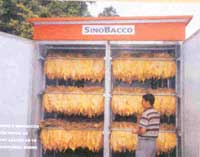

Solar barn

|

Profile barn

|

- This method is adopted in almost entire virginia cigarette

tobacco areas of Uttar Pradesh, Madhya Pradesh, Orissa, Andhra

Pradesh and Tamil Nadu.

- The flue-cured tobacco was first used for chewing purpose

but later, its mildness and low nicotine content made it popular

as a smoking tobacco.

- The cigarette smoking came into existence since 1880-1890

and it became increasingly popular with its manufacture from

flue-cured Virginia tobacco.

- Now every priced cigarette is prepared with flue-cured tobacco

having a certain proportion of other types of tobacco got

from sun-curing like Natu tobacco of Andhra Pradesh.

- The production technique of flue-cured tobacco is little different

from other types.

- It is raised with low nitrogen supply.

- Harvested at an advanced stage of maturity so that the tobacco

might become rich in starch and poor in nitrogenous substances

like nicotine at the time of harvest.

- The leaves are always harvested by priming 3-4 leaves at time.

- The harvested leaves are strung on sticks and then stacked

into a specially constructed flue-cured barn which is artificially

heated with gradual increase in temperature until the leaves

dry.

- In the production of FCV tobacco nearly 27 per cent of the

total cost of production is being spent towards curing. In

order to reduce the cost of production, especially in curing,

improved technologies have been developed.

- Adoption of low profile barn which is an improved verson over

conventional barn (7.32 m x 4.88 m x 3.2 m) will help in accommodating

120 sticks more (about 250 kg of green leaf) in the barn.

About 185 kg of coal and 20 hours of time per charge can be

saved by adopting this improved design.

- Solar area is designed to utilise solar energy for curing

of tobacco to save non renewable source of energy.

Top

Top

Sun Curing

- In sun-curing the source of energy is solar-heat. Sun

curing is commonly adopted in Tamil Nadu, Andhra Pradesh,

Bombay, Bihar, U.P., Punjab and West Bengal.

- In this method of curing

- Whole plant is strung on string or rack (as in case of chewing

and cigar tobacco in Tamil Nadu) or

- Whole plant is spread on the ground (as in case of bidi tobacco

in Bombay, hookah and chewing tobacco in U.P. and Punjab)

or

- Otherwise primed leaves or separated leaves with pieces of

stalks are tied into bundles and strung on ropes (as in case

of Natu tobacco in Andhra Pradesh) or

- These leaves are spread on the ground (as in case of chewing

tobacco in U.P. and hookah tobacco in W. Bengal)

- The method differs from place to place and type to type of

tobacco. Cigar and chewing tobacco in Andhra Pradesh takes

about 15 to 20 days and Natu tobacco takes around 45 to 60

days for curing.

- The leaves are separated from the stalk after the plants are

initially wilted in the field and the leaves are then strung

on bamboo poles for curing in the sun.

- The hookah and chewing tobacco in Bihar are harvested and

left in the field itself upto 4 to 6 days for drying after

which they are heaped for two days.

- Again they are spread and dried for 6 days then heated for

two days and spread thereafter upto 4 days for drying.

- Thus after 45 days the leaves attain dark brown colour after

which they are stripped and tied into bundles of 25 to 30

leaves for fermenting in bulks.

- Fermentation

- Smoke curing

- Shade curing.

Top

Top

|